Architects, contractors, masons and manufacturers are all in the business of building structures that are beautiful, interesting and functional. Everyone has their own role in the development process, but there are many ways that your interests overlap.

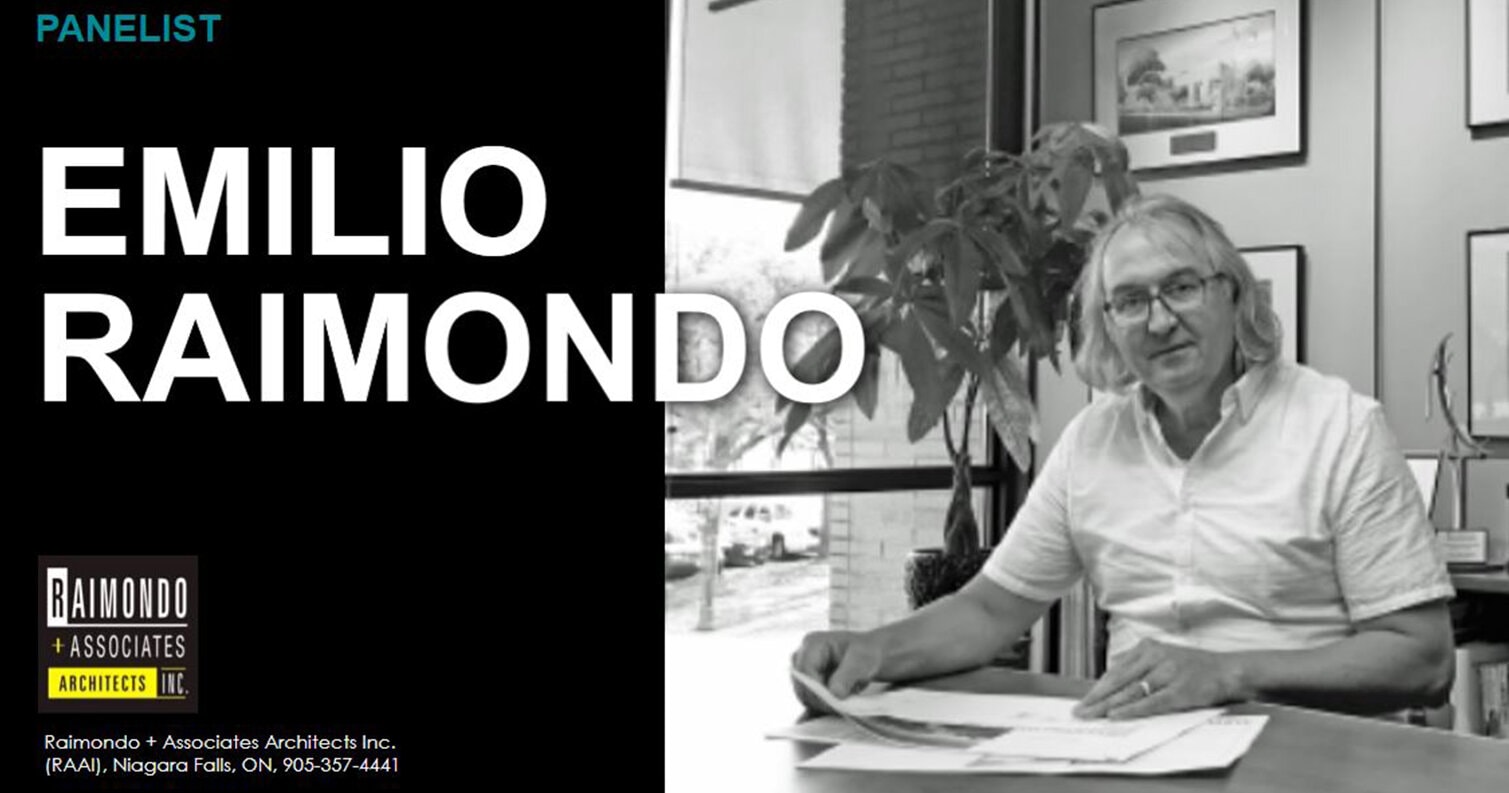

For those of us involved in creating the spaces where humans work, live and play, a recent webinar provided a venue for connection and learning. It was presented by Bob Sanders, Director of Sales at Shouldice Designer Stone, alongside experienced architect Emilio Raimondo of Raimondo & Associates Architects, and Mike Gibbons Product Development & Quality Manager at Shouldice Designer Stone, who provided technical insight.

Here are some of the key tips and takeaways from this recent webinar, Creative Minds: Trends & Innovations in Stone Veneer and Architecture in 2022.

Tips to control cracking

Cracks in the masonry of a building are not something you like to see. They can be caused by various factors including drying shrinkage, differential movement, temperature changes, structural overload, settlement or excessive deflection.

You may not be able to prevent cracks entirely, but there are several actions you can take to minimize their impact. The best steps you can take are to properly install control joints, use horizontal reinforcement and slip panes, and keep materials dry.

It’s also possible to make control joints less visible and still effective with strategic placement. Where there are changes in wall height, near one end or both sides of a door or window opening, or next to corners or intersections of walls are also ideal. Use a panel length to height ratio of 1.5:1, with maximum spacing of twenty feet (6.1 metres).

Though less common in residential building, horizontal wire reinforcement is also one of the best ways to control cracking, especially if you’re using multiple materials.

What to do about differential movement

Mixing materials on an exterior is increasingly popular, but some in the industry are hesitant about putting concrete masonry units like stone veneer with other materials like clay bricks due to the ways different products expand or contract in different conditions once on a wall. For instance, concrete has an overall tendency to shrink, and structural steel and clay bricks tend to expand.

While this differential movement may a reasonable concern with subpar installation, done right, there is nothing to worry about. The easiest way to get around differential movement of materials is to use slip planes. Where you have your clay to concrete transition, include slip planes, flashes and horizontal wire every 16 inches up the wall. Adjustable ties between veneer and the structural wall are also a valuable addition. For the best structure use both ties and horizontal wire reinforcement.

Shouldice Designer Stone has detailed guides for placement of these features, and ASTM technical documents are also a valuable resource to have with you when installing in the field day to day.

How to prevent efflorescence and lime scum

Efflorescence and lime on walls are a common frustration in the industry. The stains come from soluble salts or undissolved lime that appear on a wall due to heat or water. With proper care, these issues can be minimized or eliminated.

For efflorescence, added salts can get into a product during manufacturing because of softeners in the water system, or from exposure to salts during storage outdoors during transportation or at a job site. Once a cold product starts to warm, the stone starts to breathe again and pulls salts to the surface. Store products carefully and be sure to avoid salt exposure. At Shouldice, water softening systems are bypassed for anything to do with production, and no salts are used in the production yard.

Lime scum is an issue from the mortar, and masons can avoid this problem by putting in flashing under the sills. A sill can only absorb so much water until it passes through, and if it passes through the wall without flashing beneath it, it’s just pulling the salts and lime down that wall, behind the wall, and then back out as scum.

Installing flashing under a sill permits water to come out the bottom of the flashing, so it runs away in a drip and does not hit the rest of the building on the way down. Weepers are also crucial for allowing water and moisture to escape. These features are necessary to prevent mould growth, promote drying of the wall cavity, direct water to the exterior and prevent efflorescence and lime scum.

Trends in style and materials

Thinking about form, function and proper installation are important for safe and desirable buildings. But humans care about more than just function; creative expression and presentation are part of human history too – so of course this industry must pay attention to what looks good, what’s popular and how a building makes people feel.

Twenty plus years ago, masonry was used for whole projects, covering all four sides of a structure. However, in more recent years, mixing materials on a structure has become more the norm – whether it’s glass, siding, stucco or steel alongside stone veneer concrete masonry units.

Continuing to lead the way for exterior colours are captivating ultra-white and jet black. They lend themselves to crisp lines, and multiple block heights, such as two-, four- and eight-inch heights together.

Charcoals and dark greys remain popular too, such as Shouldice Stone's Architectural lineup in Executive Gray and Estate Stone in Norton. But hints of brown, tan and subtler earth tones are emerging with new trendsetters. They can be seen in the Chamois colour of Rock-Stone and Brockton colour of Estate Stone.

Beyond colour, mixing texture is trending as a way to break up a design and add contrast, with Shouldice’s Rock-Stone and Tapestry finishes being most popular.

For more insight, including details on fire resistance ratings, technical tips, and more, watch the webinar and sign up for the Shouldice Designer Stone newsletter.