What's New

We are thrilled to introduce our new product, featuring sleek lines and a streamlined layout that maximizes efficiency.

Learn More

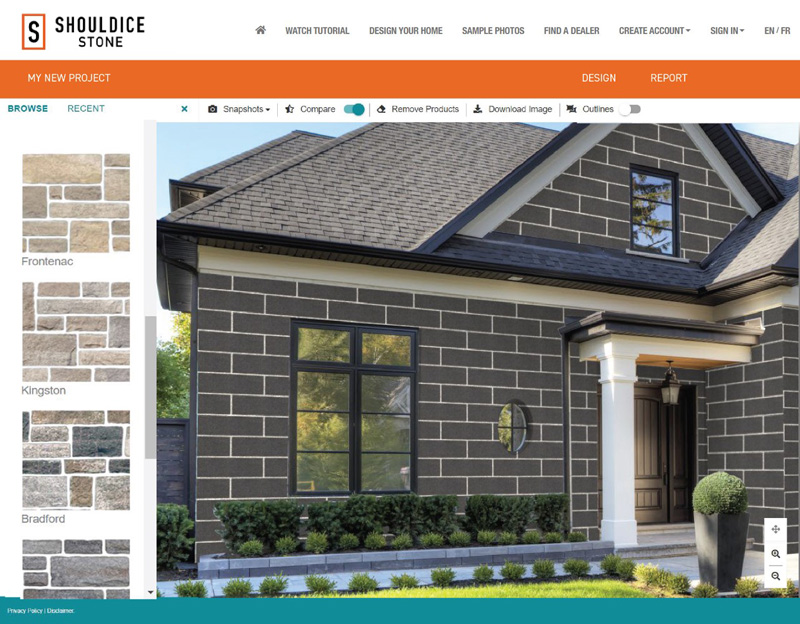

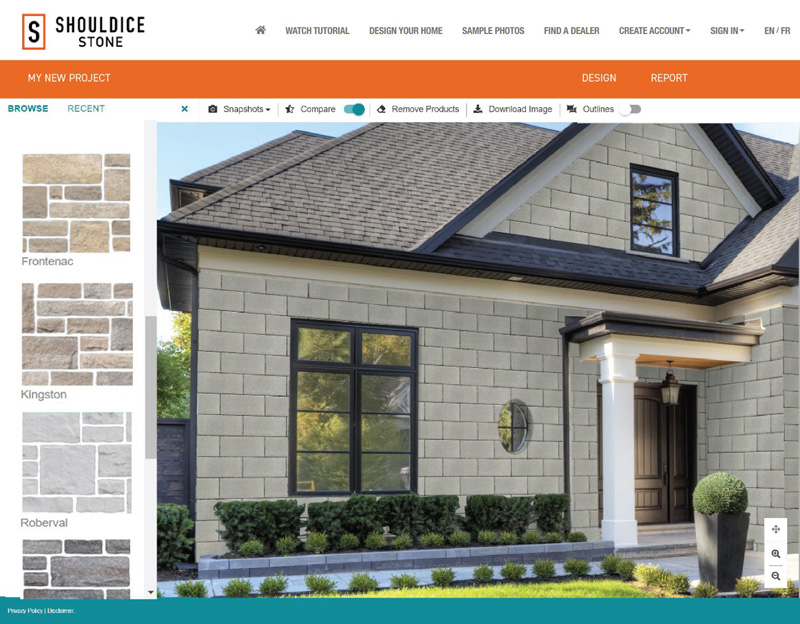

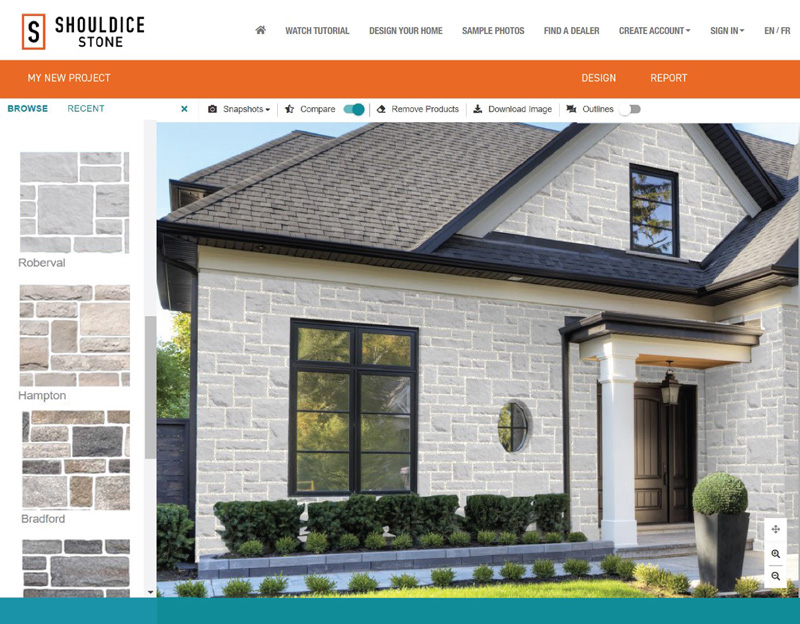

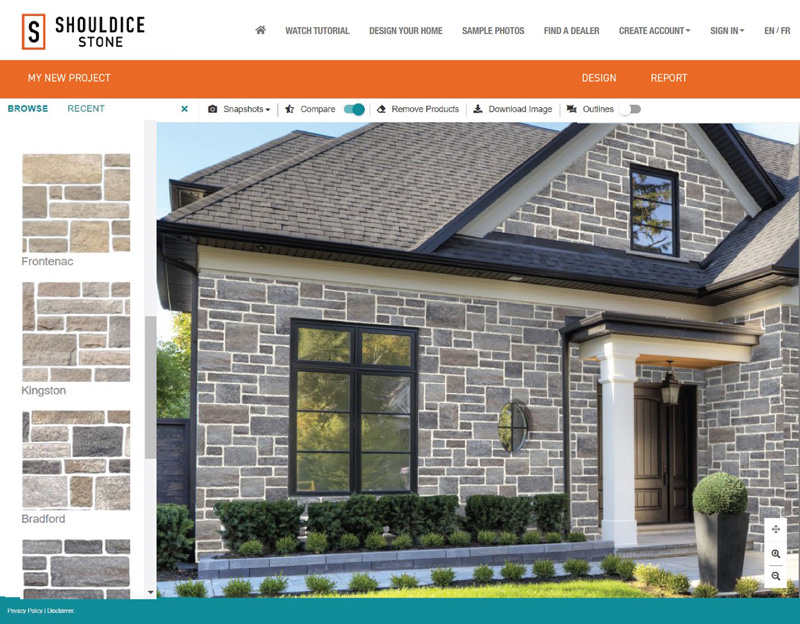

Use our Visualizer tool to see how our various products will look on your home.

As a third-generation, family-owned company, we take immense pride in our customer service. We are not happy until every one of our customers is happy.

Ninety per cent of our materials are sourced from within 25 km of our Shallow Lake, Ontario, manufacturing facility. Our in-house R&D team continually looks for ways to make our products and processes more sustainable.

Our lineup of stone and brick products can be used to create any style of building, from a classic country farmhouse to an ultra-modern high rise.

Shouldice offers a lifetime warranty provided the initial purchaser is the product owner, the products are used according to local building codes and the products are installed according to specifications and installation guidelines.

At Shouldice Stone, we understand the importance of seamless communication and reliable support for professionals like you. By clicking the button below, you can provide us with information about your upcoming project or any inquiries you may have and one of our experienced sales representatives will promptly get in touch with you.

Shouldice Stone has over 75 years of quality,

service, and innovation experience that have made

us a leading manufacturer you can rely upon.

Copyright . Shouldice Stone. All Rights Reserved.

Privacy Policy |

Terms & Conditions

Sign up here for our free monthly newsletter to learn about the latest design trends, our newest products and more.

"*" indicates required fields